LENOX MetalMax Diamond Grit 7-in Cutting Wheel 1972924

$19.99

Out of stock

The METALMAX wheel’s body is made of solid steel to greatly reduce the risk of breakage. The combination of a steel body with a diamond edge allows METALMAX to hold its original wheel diameter until the very last cut, meaning better control, reach, and cut precision throughout the wheel life.

- Delivers 1,000 or more cuts without changing the wheel and 30X longer life than thin bonded cutoff wheels

- Advanced diamond technology provides extreme durability in metal cutting applications, for increased productivity, reduced downtime, and a lower cost per cut compared to thin bonded cutoff wheels

- Solid steel wheel body greatly reduces risk of breakage for added safety

- Diamond construction maintains original wheel diameter and cutting depth throughout the life of the blade for better control, reach, and precision

- Recommended for steel, sheet metal, stainless steel, rebar, cast iron, aluminum and non-ferrous metals; when cutting aluminum, it is recommended to apply cutting wax or other type of saw lubricant to avoid chip welding

- Designed for use in the same power tools as bonded abrasive wheels, at the same RPMs and feed forces with no changes in operating settings required

- Wheel does not wear down like bonded abrasives and produces less odor and dust residue compared to thin bonded cutoff wheels

- Wheel thickness: .06-in (1.5mm)

- For use with 7-in angle grinders and circular saws, maximum RPM 8,400

| Weight | 2 lbs |

|---|---|

| Dimensions | 7 × 7 × 1 in |

| Brand | LENOX |

| MPN | 1972924 |

| UPC |

Related products

$24.99

Bolt Cutters

$19.99

$17.99

$300.00

$24.99

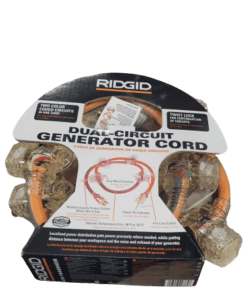

Conduit & Fittings

$22.99

$14.99